Posted by Faxon Firearms Staff on Apr 15th 2016

What is “Headspace”? Why is it important? And how does one check it in a Modern Sporting Rifle?

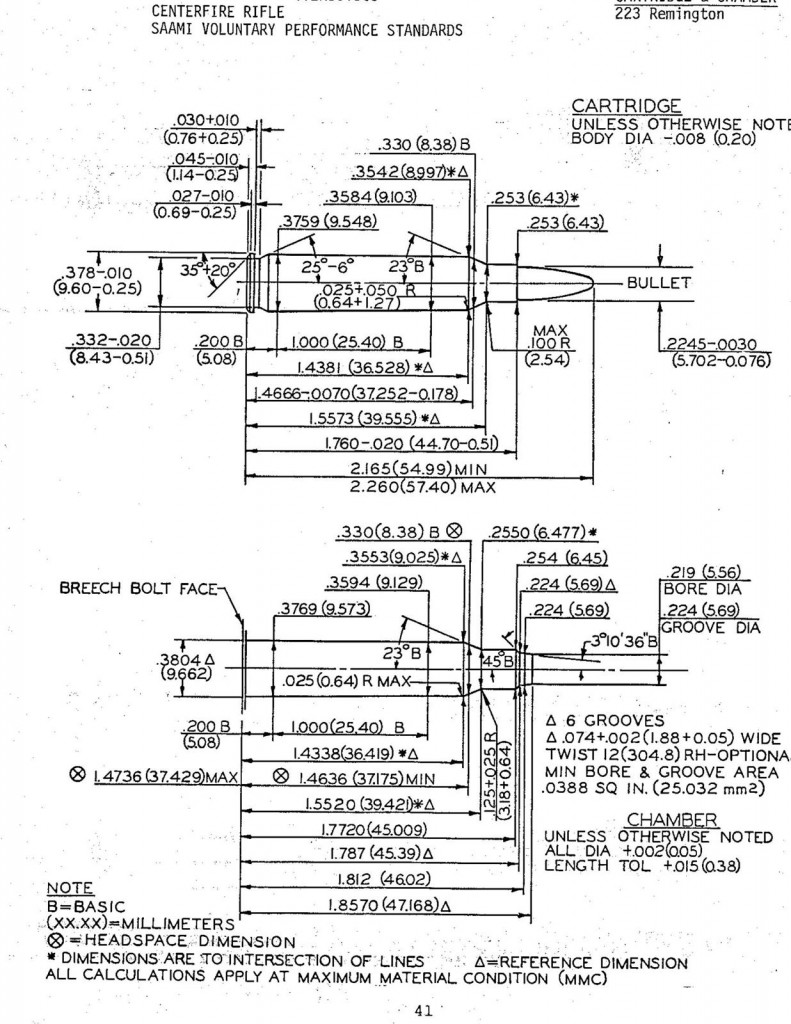

“Headspace” refers to the total length of the chamber of a firearm in its locked position. It is an absolutely critical dimension for the safe and effective operation of a firearm. Typically this distance is measured from a datum on the shoulder of the case (common for rifles) or the front portion of a case (common for handguns) to the face of the bolt where cartridge sits. For obscure, magnum, or other chamberings, the datum can vary.

Having too much headspace (chamber is long) can result in gases escaping around a case, burst primers, and not having containment on a detonation; or the case coming off the bolt face and detonating unsupported. Having too short (chamber is short) can put a round into compression, causing pressures to spike past the rated containment of the chamber. In any case, having a headspace rating outside SAAMI (for US customers) or CIP (for Europoean/ROW customers) can have a potentially catastrophic effect including injury or death.

A very small error in headspace can result in very large problems.

An example of the SAAMI specification for the .223 Remington is below with headspace called out:

Faxon Firearms 100% checks all its barrels for function with nominal headspace using bolts and depth gauges precision ground to the exact nominal tolerance on the given caliber’s bolt. This is symbolized by the paint dots on the top of the extension. One dot means that the extension is properly torqued to spec and the other dot is color-coded to a specific operator who hand-checks all barrels using the precision gauges.

Faxon recommends checking headspace with the customer’s intended bolt and barrel. Individual bolt and barrel combinations will vary due to tolerance variations in manufacturing. This check should be completed by a gunsmith or by the end-user with appropriate gauging and a full understanding of what constitutes headspace and the consequences.

Checking headspace for nominal function requires two gauges a “Go” gauge and a “No Go” gauge. The “Go” gauge is precision ground to the minimum acceptable headspace requirement for the chosen caliber. The “No Go” gauge is ground for the bottom edge of the nominal function of a given cartridge. Important- a “No Go” gauge can fit in a chamber and it is still safe to fire. Checking for the maximum depth of a case is commonly done by a “Field” gauge, which is ground the maximum safe dimensions of a caliber.

While specific calibers vary, there is usually about .003” - .004” between the minimum chamber depth and the maximum nominal depth. This is a relatively small window, but Faxon will not release a barrel without ensuring 100% of our barrels are within this specification. Of note, there is typically another .0010” between maximum nominal and maximum safe depths (about .0015” total from min to max chambers) for most calibers.

To Check Headspace:

Getting Started:

- Purchase a set of ground headspace gauges. Faxon strongly recommends Pacific Tool & Gauge headspace gauge sets. Other companies have been known to have variations in their production.

- Remove any sprung ejector or similar from the face of the bolt. The gauge must be able to sit in the bolt face without issue.

- If the barrel is installed in the firearm, leave the extractor in place. If the barrel is being tested separate of the action, the extractor can be removed.

- Clean out the chamber and bolt face of any debris

Important- Check headspace with gauges marked for the specific caliber.

Checking Minimum Depth:

This step is to check that the chosen bolt and chamber is not too tight.

- With the “Go” Gauge, drop the gauge into the chamber.

- Insert the bolt into the extension and attempt to rotate.

- The bolt should rotate with minimum slop. It may be tight, so long as hand pressure can rotate the bolt, the chamber and bolt pass.

Checking for Nominal Depth:

The “No Go” is ground to the maximum nominal depth of the chamber for ideal performance, longevity, and accuracy.

- With the “No-Go” Gauge, drop the gauge into the chamber.

- Insert the bolt into the extension and attempt to rotate.

- The bolt should NOT rotate under hand pressure. The bolt lugs should not be able to rotate and push the bolt into battery.

- oIf the bolt does not rotate, the specific barrel and bolt combination is at a nominal depth. It is safe to shoot.

- oIf the bolt does rotate, the specific barrel and bolt combination may be safe to shoot. Further testing is required with the field gauge.

Uh-Oh! My bolt was able to close on “No-Go”. Does that mean my combination is bad?

No! Further testing is required, but the barrel/bolt combination passes “Field” gauges, your firearm is safe to shoot.

Checking for Maximum Depth:

“Field” gauges are ground the maximum allowable tolerance for a chamber.

- With the “No-Go” Gauge, drop the gauge into the chamber.

- Insert the bolt into the extension and attempt to rotate.

- The bolt should NOT rotate under any pressure. The bolt lugs should not be able to rotate and push the bolt into battery.

- oIf the bolt does rotate, DO NOT use the chosen barrel and bolt combination. If the bolt rotates, it means the chamber and bolt in combination are too loose. Shooting may result in a catastrophic malfunction. Contact the manufacturer for repair/replacement.

- oIf the bolt does not rotate, the specific barrel and bolt combination is safe to shoot, it just may not have maximum accuracy. The barrel should be monitored with further testing every 1,000 rounds to ensure any wear does not push the bolt/barrel combination past the maximum specification.

I want my barrel to be at nominal, but I am closing on the “No-go” gauges. What should I do?

Given Faxon’s quality control, the likely culprit to the issue is the variation in machining bolts to “Mil-Spec”. We’ll post up again on details for bolt manufacturing and how to troubleshoot if your bolt is out of specification.

We encourage customers to contact us for any advanced troubleshooting. Our team enjoys being of service to all our customers.

How do you guarantee that a bolt and barrel combination will be nominal headspace?

Unfortunately, it’s impossible to do so between various manufacturers all operating on “Mil-Spec”. Even for all parts made in-specification tolerance stack-up can and does happen. Faxon manufactures its parts to tolerances tighter than “Mil-Spec” and most parts can and do match up to nominal, we cannot guarantee other manufacturer’s parts will combined to pass nominal specifications.