Posted by Faxon Firearms Staff on Nov 28th 2022

Rifling of a Barrel: A Complete Guide

Rifling of a Barrel: A Complete Guide

Barrel rifling can be a confusing subject even for experienced gun owners. Between all the various types (Button, 5R, Polygonal, etc.) and some of the marketing hype surrounding different methods, it can be difficult to decide what is best for you.

To help with this, we’re going to take a deep dive into barrel rifling, from the very basics to all the intricacies between the various different types of rifling.

Let’s start with some basics and then we’ll dive into the more detailed comparisons towards the end.

What is Rifling?

The rifling of a barrel is the spiraling pattern of grooves inside of the gun barrel that imparts spin to the bullet as it travels from the chamber to the muzzle. The differences come in with the way the rifling is put into the barrel and how the lands and grooves (high and low spots) are machined into it, and the pattern of lands and grooves.

The goal of each type of rifling, no matter how it is set up, is to spin the projectile so that it rotates as it travels through the air. This spin, technically gyroscopic stabilization, is essential for the accurate flight of a bullet and is what gives rifled barrels such an advantage over smoothbore barrels.

Think of a football player throwing a tightly spiraling ball versus someone just hurling the ball end over end through the air. A spinning projectile is effectively self-centering along the axis perpendicular to the direction of its spin. In simple terms, if it’s spinning through the air instead of tumbling, it will fly a longer distance with much greater accuracy at higher velocities.

When Was Rifling Invented?

The concept of rifling was first introduced, as best we can tell, in Austria around 1498 and in Germany by August Kotter in 1520. There are also earlier examples in Europe and China of archers and then gunners who realized that spinning projectiles flew straighter, but nothing has been verified.

Either way, it wasn’t until the 1800’s that we started to see the widespread use of rifling in firearms as metalworking advanced to the point where the grooves in the rifling no longer had to be cut by hand.

Steam-powered lathes and other rotary tools, plus improvements in metallurgy and machining made the manufacturing process of rifled barrels much more straightforward and consistent. During the years leading up to the civil war in America, rifling barrels became common on firearms all over the world.

Types of Rifling

Button Rifling

Button rifling is a cold-forming process that swages the barrel with a carbide tool (a button) that has specific grooves for the dimensions and twist rates that are desired for the final rifling of the barrel.

It’s done in a single pass, which means if you get it wrong, you’re basically out of luck, but it does make for a very repeatable process as there are no metal chips to control and the surface of the barrel is work hardened for increased durability.

Single Point Cut Rifling

Single-point cut rifling, also sometimes called hook rifling, is not the most economical method, as it is very slow. This method uses a carbide “hook” to cut a single groove over many passes. Cut-rifled barrels are made slower than single-pass methods, but it gives a great degree of control over the depth of each groove.

It also does not stress the material of the barrel, which eliminates the need for a stress-relieving step later in the process.

The downside is that rifling grooves in this way is time-consuming and difficult to get consistent results with. However, when you get the process down, cut-rifled barrels can produce match-grade results. Due to the time and effort necessary to perfect the cut-rifling process, cut-rifled barrels are not the most economical options, and are often expensive.

Broach Rifling

Broach rifling is a cutting process that uses a long, multi-toothed tool that gradually removes small amounts of material from each groove. The broaching tool is pushed down the barrel at a rotational rate that matches the desired twist rate, and each progressively taller tooth takes more and more material from the groove.

This is a great option for speeding things up over single-point cutting because it’s a single-pass operation. The downside is that it’s a headache for machinists because the broach itself is fragile and rather costly, and you need a new one for each twist rate.

You also generally need to polish or line the interior of the barrel afterward to get a good surface finish. Still, this is a great method if done properly, and doesn’t impart any additional stress on the barrel.

Polygonal Rifling

A polygonal barrel is a popular style of rifling for pistol barrels that was heavily popularized by Glock and has now been adopted by a number of other manufacturers as well. The general idea is to improve barrel life by reducing the sharp edges of the lands of the rifling.

This reduces erosion of the barrel and generally makes cleaning easier as well.

5R Rifling

5R rifling is a relatively new change to the pattern of grooves cut into the barrel to rifle it. Essentially, it uses a shallower angle to the grooves to create a smoother transition from the top of the land to the bottom of the groove, similar to polygonal rifling in some ways.

It also uses an alternating land and groove pattern so that there are never two lands across from each other, which lowers the pressure on the bullet and thus improves the longevity of the barrel.

It also reduces the deformation of the projectile which increases consistency from shot to shot and doesn’t force as much of the projectile material into the grooves.

So, in other words, less time is spent cleaning copper fouling out of the grooves of your barrel, which greatly speeds up cleaning and maintenance overall.

Cold Hammer Forging

Cold hammer forging is a process where a bored-out barrel blank with a polished smooth hole bored through the center is hammered into shape around a rod (technically called a mandrel) with the inverse of the desired rifling pattern cut into it.

So, when the metal is hammered, it compresses against the mandrel, leaving you with the rifling impressed into the bore. This process is very consistent and creates long-lasting barrels, but it requires a lot of investment upfront for a benefit that very few shooters will realistically utilize.

Electrochemical Machining (ECM)

Electromechanical machining is a relatively new process that uses copper combined with salt water and an electrical current to remove material in what is essentially the inverse of electroplating.

This allows for material to be removed in very cheap setups, with some ECM setups costing just a few hundred dollars, making this a favorite among DIY gunsmiths. As of yet, the process isn’t as precise as other methods and hasn’t become economically viable for widespread production.

That said, it is a neat technology and arguably the cheapest way to rifle a barrel for the average DIY barrel maker.

Other Methods of Rifling

New and experimental rifling designs are being worked on all the time, from progressive or gain rifling to extended-range full-bore (EFBR) designs that use projectiles that are machined with inverse lands and grooves that fit into the rifling of the barrel.

There are essentially as many ways to rifle a barrel as there are to cut or erode a metal barrel blank, so new techniques are being experimented with all the time. There are also new land and groove designs (like 5R) that change the geometry of the rifling cut to achieve various benefits.

Twist Rate

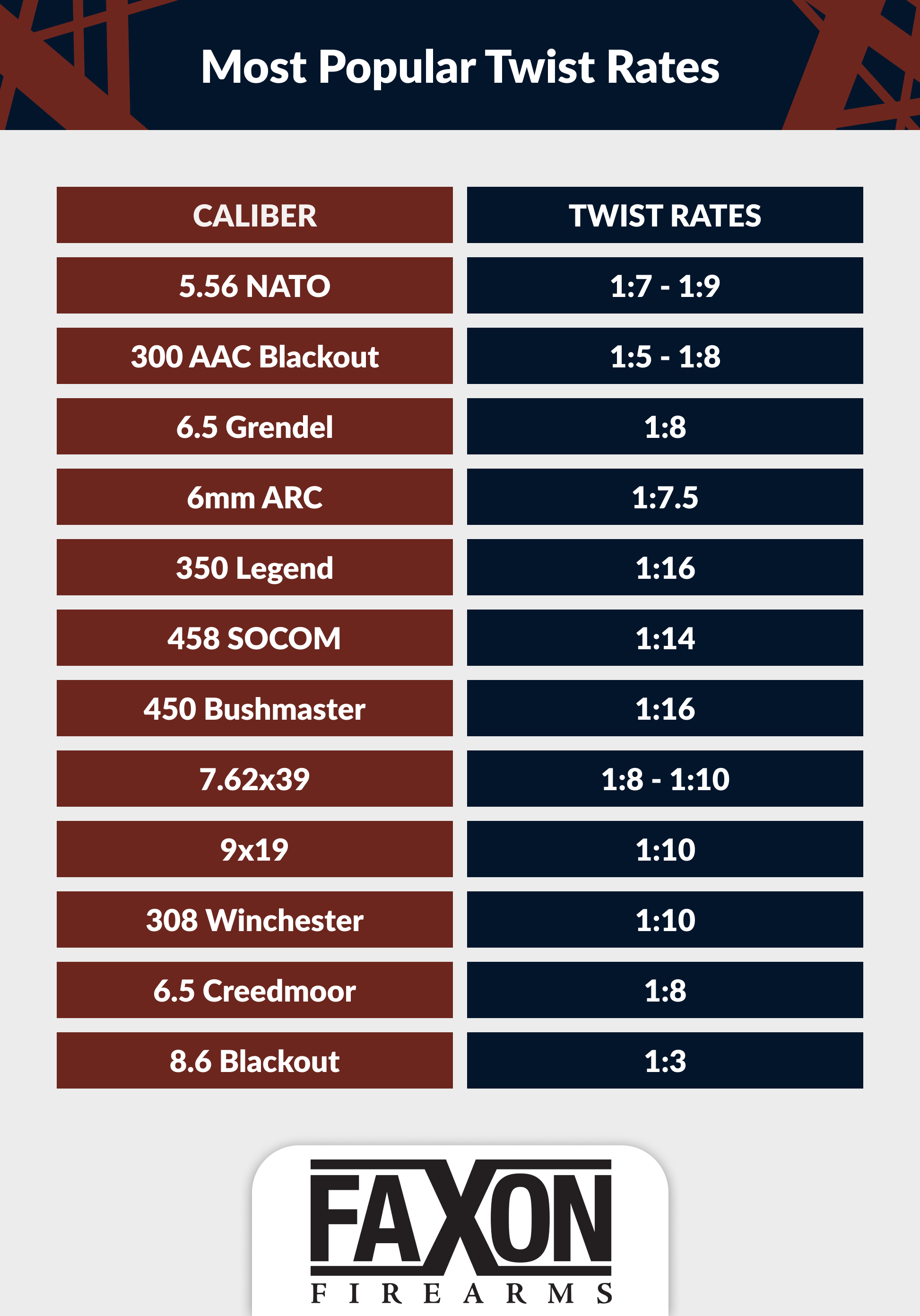

Lastly, and arguably most importantly, twist rate is a vital part of rifling that can greatly impact the performance of a firearm and its projectile. The rate of twist is generally expressed as a ratio of one rotation to the distance it takes to complete it in inches.

So, a 1:7 twist barrel will have rifling that completes one 360-degree rotation every 7 inches. A 1:12 twist will cause the bullet to complete one full revolution every 12 inches, and so on.

As a general rule of thumb, heavier bullets will require a faster rotation to fully stabilize them, while a lighter bullet needs a slower rotation in order to prevent overspin, which can impart additional movement to the bullet as it travels through the air. This brings up the concept of “fast-twist” rifling which has gained popularity in recent times with 300 Blackout and 8.6 Blackout. Fast-twist rifling is no different than your standard rifling, it just spins the projectile much faster as it travels from the chamber to the muzzle. This translates to a higher level of energy that is delivered downrange on the target due to the speed at which the projectile is rotating.

It’s important that you pair your barrel’s twist rate to the weight of the projectiles you’ll be shooting for the best results. There are general-purpose twist rates for most calibers that will sit somewhere in the middle and be good all-rounders, but the best performance comes from getting the right twist rate for your bullets.

Pistol and Rifle Barrels from Faxon Firearms

At Faxon Firearms, barrels are our bread and butter. We made our name in the industry on the strength of our barrel designs, and we continue to innovate with new technologies like 5R rifling and improved metallurgy.

We offer a variety of high-quality barrels for popular platforms such as Glock handguns and AR-15s, and our lineup is constantly expanding with new offerings that continue to perform with the very best in the industry.

We also offer uppers, lowers, BCGs, and complete firearms as well, and are proud to help push the firearms industry forward with new innovations and better manufacturing standards every year.